Ledgestone products have always been one of our more popular Building Stone Veneers. In the past few years its popularity has become even more obvious as industry influencers continue to promote the linear look of ledgestones. It’s a look that easily translates into the perfect balance of trendy and timeless. The combination of horizontal lines and authentic natural finishes sets the stage for a look that can pull off an all-in-one contemporary and rustic solution. With the popularity of Ledgestones continuing to rise, we introduced Tailored Ledgestones in 2016. Let’s take you through some of the stylistic differences and color influences. If nothing else, enjoy some inspiration!

Traditional Ledgestone Veneers

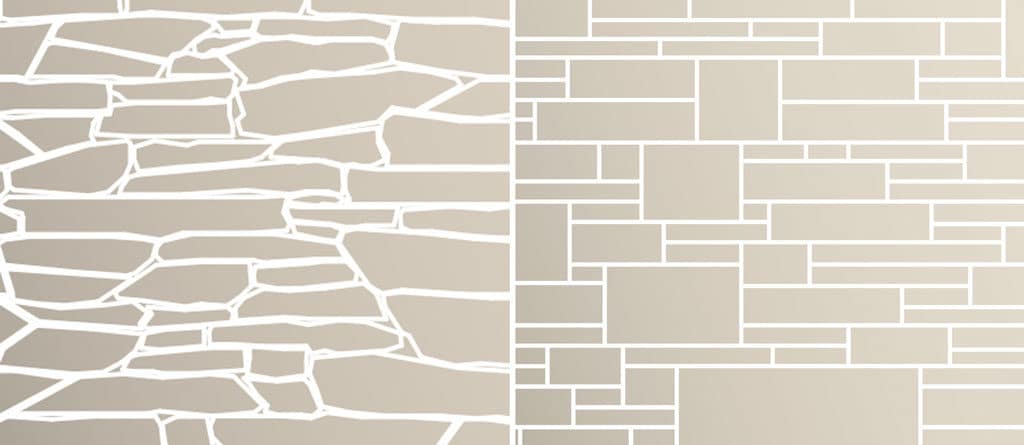

A finished stacked stone or grout installation in the ledgestone pattern of stone installation is most simply characterized by a rise of 4″ or lower. The origin of ledgestone dates back to a practical building stone masonry solution for early American settlers as a simple form of veneer stone installation for foundations, chimneys, and wall stone. The thin layers made for easier dry stack stone installations and required less skilled stone masons because the lower heights were easier to course. Although it may be an easier installation, the use of smaller pieces can sometimes add to the overall stone installation time.

Our list of original Ledgestone products includes Chilton Ledgestone, Chilton Rustic Ledgestone, Cinnamon Bark Ledgestone, Fond du Lac Ledgestone, Fond du Lac Rustic Ledgestone, and Whispering Pines Ledgestone. Along with being on Buechel Stone’s original go-to short list, these tend to be more historically accurate ledgestones. The heights come from the natural cleft (natural stone that is split parallel to its layers in the ground, yielding a surface that is irregular to a degree that corresponds with the flatness of the material’s layering) of the stone as it is formed in the quarry. Heights are 4″ or or less, so installation tends to be a little more tedious. Also, since the heights are completely random it takes more of an eye to get a good dry stack look.

In 2017 we introduced Barnwood Blue Ledgestone, Black Frost Ledgestone, Highland Scotch Ledgestone, and Spalted Oak Ledgestone to grow our Ledgestone collection according to color trend forecasting. And 2017’s new stone veneers are now providing new inspiration as project photos in our Brag Book. As our traditional Ledgestones continue to influence future trends, the progression of trendy and timeless continues.

Tailored Ledgestones

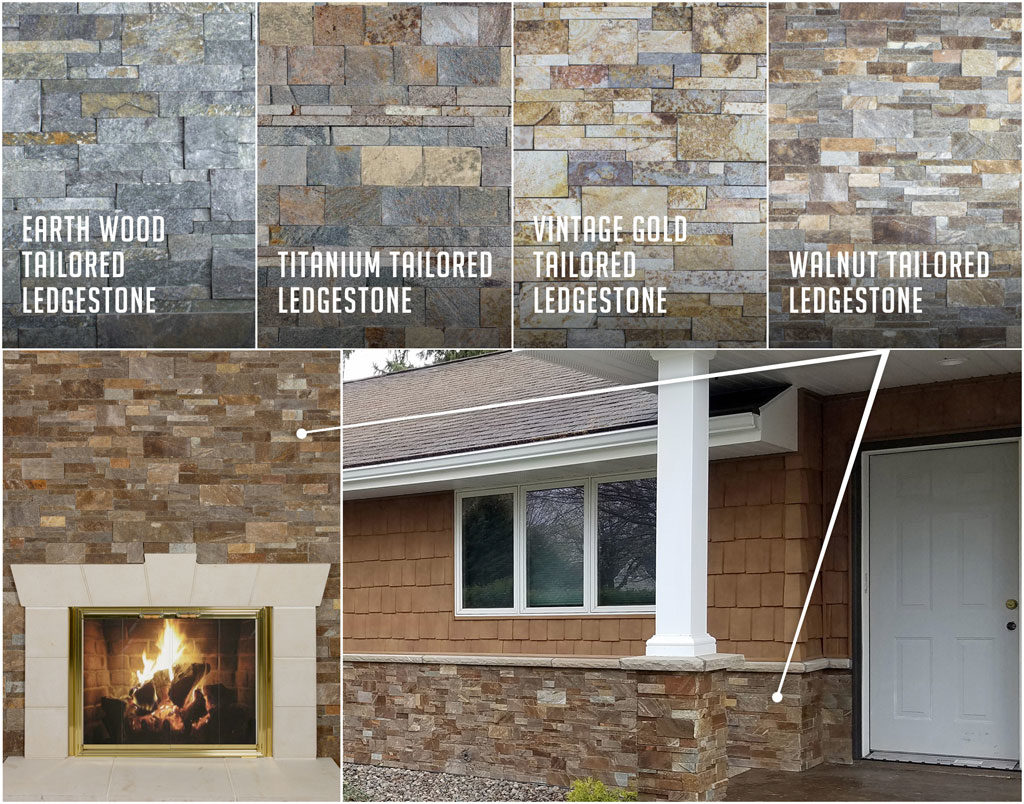

Our Tailored Ledgestone line has four products: Earth Wood Tailored Ledgestone, Titanium Tailored Ledgestone, Vintage Gold Tailored Ledgestone, and Walnut Tailored Ledgestone. And these are a little different than the traditional, normal ledgestones you may have seen. Different options on the market are made by gluing together real stone or manufactured stone pieces to create pre-formed ledgestone “panels”. Depending on the manufacturer or fabricator, other industry terms for these types of ledgestone panels include: stacked stone ledger panels, ledger stone panels, thin stone panels, stone veneer panels, ledger stone tiles, stone wall tiles, or stacked stone tiles.

There’re a few potential issues with ledger stone panel and stacked stone tile products. First, they are typically glued poorly. Because of this, it’s often easy for water and moisture to get in between the stone pieces. This can cause huge problems for exterior stone veneer installations. The other thing to watch is the pattern. Even though they are assembling all of the smaller ledgestone pieces into one veneer stone panel, they all tend to end up being the exact same size. This can lead to a visible repeating stone pattern in the installation. We’ve seen quite a few manufactured stone panel or stacked stone wall tile installations result in a checkerboard look – not good.

Stacked Stone Installation Customization

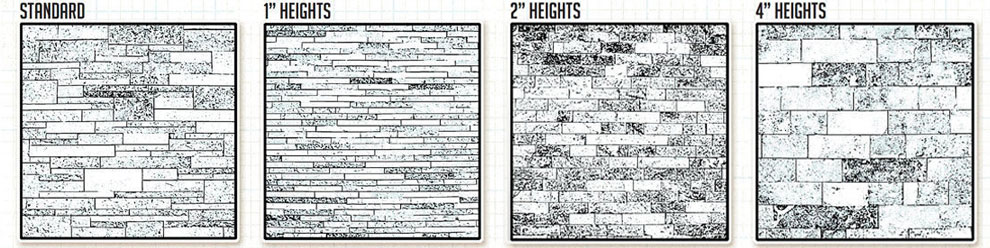

Because we pride ourselves on being with you from concept to completion, we designed our Tailored Ledgestone veneers to be “tailored” to your needs. They were created with your project vision in mind. We lessen the likelihood of the telltale checkerboard stone patterning caused by ledgestone panels by providing pieces of individual stone. Each natural stone piece in our Tailored Ledgestone products is an individual stone that is sawn on the top, bottom, and ends. The stones are packed in a 33 percent blend of 1″, 2″ and 4″ heights. These heights allow for an easy 2:1 pattern installation. A two to one pattern is when you have two small heights (in this case, two 1″ heights to one 2″ height). The individual pieces mean each height can be run in courses, similar to how you install brick where all of the heights are in a running bond. You can also custom order any Tailored Ledgestone product in one height only, to give uniformity and coursing on each layer. (*Additional cost for product in all 1″ heights.)

Without the restrictions of ledger stone panel systems, stylistic preferences could be implemented during the veneer stone installation for unlimited color and pattern options. The sawn heights meet increasing demand for modern design trends in both interior and exterior stone veneers and perfectly align with your vision of what a stacked stone masonry installation should look like.

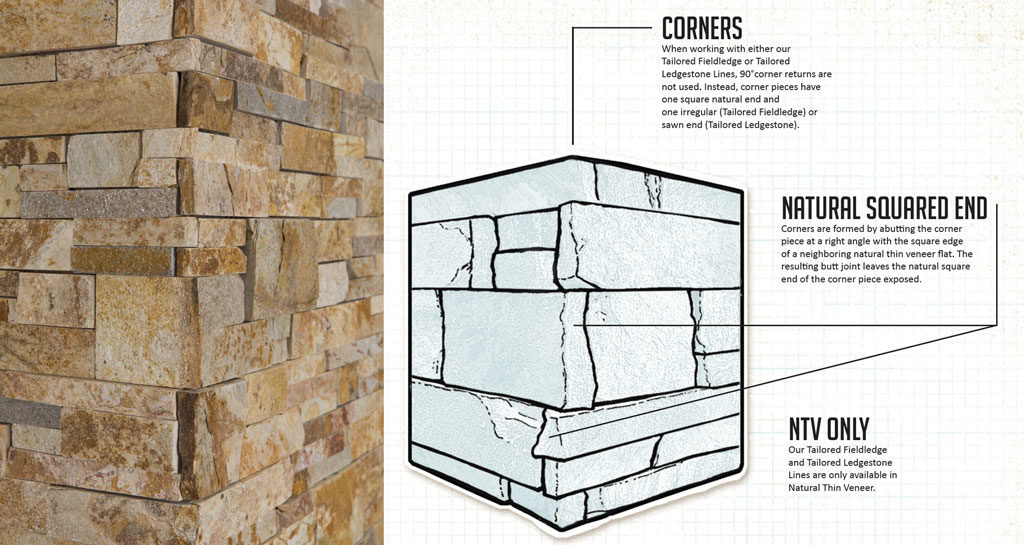

Tailored Ledgestone Corners

Both our Tailored Ledgestone and Tailored Fieldledge Lines are only available in Natural Thin Veneer. Another thing to remember about these product lines is the corner installation is a little different than other thin stone veneer installations. When working with either our Tailored Fieldledges or Tailored Ledgestones, 90° corner returns are not used. Instead, corner pieces have one square natural end and one irregular (Tailored Fieldledge) or sawn end (Tailored Ledgestone). Corners are formed by abutting the corner piece at a right angle with the square edge of a neighboring natural thin veneer flat. The resulting butt joint leaves the natural square end of the corner pieces exposed, as shown in the below illustration and picture of a properly veneer stone corner installation of Vintage Gold Tailored Ledgestone.

Stacked Stone That Stacks Up

We’ve just given you the basics, and you can click on the following product category line names to view our exceptional selection of Ledgestone and Tailored Ledgestone products. For more information on natural stone masonry for ledgestones, along with our other Building Stone Veneers, check out our masonry blog. And if you have questions, get in touch– we’re here to help. Best ledgestone veneer products are just the beginning. What makes us unique is everything we do throughout your project. And providing best experiences is what gets us out of bed every morning – making us your ONLY REAL CHOICE in STONE. If you haven’t already, JOIN OUR NEWSLETTER to be notified of everything our team of Buechel Stone #Rockstars is doing to ensure a future built by your own project success stories.

Tracy Lisowe | Marketing Director

&

Mike Buechel | COO, Owner

Buechel Stone Corp.

*Editor’s Note: This post was originally published Feb. 16, 2015, and has been revamped and updated Oct. 17, 2018.